Inquiry

Form loading...

The cleaning and maintenance industry is rapidly evolving, and with it, the demand for efficient and effective cleaning solutions is on the rise. Industrial Floor Scrubbers play a critical role in maintaining cleanliness and hygiene in various sectors, including manufacturing, warehousing, and healthcare. According to recent industry reports, the global market for floor scrubbers is anticipated to grow significantly, with estimates suggesting an increase from $1.2 billion in 2022 to over $1.6 billion by 2025, driven by advancements in technology and the growing emphasis on workplace safety and cleanliness.

As businesses seek to optimize their operations, investing in high-quality Industrial Floor Scrubbers becomes essential. These machines not only improve the aesthetic appeal of facilities but also enhance productivity by ensuring a safe and clean working environment. Key features to consider when selecting an industrial scrubber include the type of surfaces to be cleaned, machine size, tank capacity, battery life, and ease of use. The right choice can lead to significant long-term savings in labor costs and cleaning supplies while also contributing to overall workplace efficiency.

In this buying guide, we will explore the crucial factors to contemplate when purchasing Industrial Floor Scrubbers, helping you make informed decisions that align with your operational goals and cleaning requirements. Whether you are upgrading an existing machine or investing in your first unit, understanding these features will empower you to select the most suitable solution for your facility's needs.

When selecting industrial floor scrubbers, understanding key features is crucial for maximizing efficiency and ensuring optimal cleaning performance. One of the foremost aspects to consider is the machine's cleaning path width, which directly impacts productivity. According to the Cleaning Industry Research Institute, a wider cleaning path can reduce the time required to cover large areas, which is particularly beneficial in expansive industrial environments. Machines with a cleaning path of over 30 inches are often recommended for larger spaces, allowing operators to clean more ground in less time.

Another critical feature is the type of scrubber—whether walk-behind or ride-on. Walk-behind scrubbers are ideal for navigating tighter spaces, while ride-on models significantly enhance efficiency for larger areas. The market research firm IBISWorld notes that the demand for ride-on scrubbers has increased by 10% in recent years as companies focus on reducing labor costs while improving cleaning standards. Additionally, the scrubber's tank capacity is vital; larger tanks allow for extended cleaning sessions without frequent refills, thus minimizing downtime. With many industrial facilities operating under stringent health and safety regulations, opting for scrubbers equipped with advanced filtration systems can help maintain air quality while ensuring the effective removal of contaminants from floors.

| Feature | Description | Importance |

|---|---|---|

| Scrubbing Width | The width of the scrubber head determines the area covered per pass. | Essential for efficiency in large spaces. |

| Water Capacity | The size of the water tank affects operational time before refilling. | Critical for reducing downtime during cleaning. |

| Battery Life | Duration the machine can operate on a single charge. | Important for preventing interruptions during cleaning tasks. |

| Cleaning Path | The length and shape of the scrubbing path can affect maneuverability. | Determinative for cleaning around obstacles. |

| Noise Level | Decibel level during operation impacts workplace comfort. | Key for maintaining a pleasant working environment. |

| Weight | The total weight can affect both transportability and cleaning speed. | Significant for ease of use and storage. |

| Tank Material | Durability of the water tank influences the machine's lifespan. | Critical for long-term reliability. |

| Filter System | Type of filtration affects the cleanliness of the reclaimed water. | Essential for maintaining hygiene standards. |

| Ease of Maintenance | How simple it is to clean and service the machine. | Important for minimizing operational costs. |

| Price Range | The cost of the scrubber impacts budget considerations. | Key for financial planning and investment. |

When selecting an industrial floor scrubber, understanding the different types available is crucial for pinpointing the most suitable model for your environment. The most common types include walk-behind scrubbers and ride-on scrubbers.

Walk-behind scrubbers are ideal for smaller areas and provide greater maneuverability, making them perfect for tight spaces such as restrooms, kitchens, and small retail areas. They are operated by an individual who walks behind the machine, allowing for detailed cleaning and greater attention to hard-to-reach spots.

Conversely, ride-on scrubbers are designed for larger facilities where efficiency and speed are priorities. These machines enable operators to sit while cleaning, which not only reduces fatigue but also increases productivity in expansive spaces like warehouses and manufacturing plants.

Additionally, there are automated scrubbers that utilize advanced technology to perform cleaning tasks with minimal human intervention. These machines are particularly advantageous in environments requiring consistent cleaning, such as hospitals or logistics centers, ensuring the floors remain tidy without the constant oversight of staff. Each type has its own set of applications, making it essential for buyers to assess their specific cleaning needs when making a decision.

When considering the performance of floor scrubbers, several key factors come into play that can significantly influence their efficiency and effectiveness. One primary factor is the design and functionality of the scrubber itself. According to a recent industry report by Market Research Future, scrubbers with advanced counter-rotating brush technology can enhance cleaning performance by up to 30%, allowing them to tackle stubborn dirt and grime more effectively compared to traditional models. This innovation not only improves the scrubber's cleaning ability but also reduces water and detergent usage, making them more environmentally friendly.

Another crucial factor impacting floor scrubber performance is the type of flooring being cleaned. Different surfaces, such as tiles, concrete, or hardwood, require specific brush types and cleaning solutions to achieve optimal results. A 2023 study by the Cleaning Industry Research Institute found that inappropriate cleaning equipment could lead to a 25% increase in maintenance costs for commercial properties due to surface damage and accelerated wear. Therefore, selecting a floor scrubber that matches the flooring type is essential for maintaining floor integrity while achieving desired cleanliness levels.

Finally, the operator's training and maintaining the scrubber play a pivotal role in its overall performance. Skilled operators can maximize the scrubber's potential through effective techniques and regular maintenance routines. A study published in the Journal of Cleaner Production highlights that facilities with trained staff experienced a 40% reduction in cleaning times, resulting in significant operational savings. Investing in training programs and ensuring proper upkeep of the scrubbers can ultimately enhance cleaning efficiency and prolong equipment life.

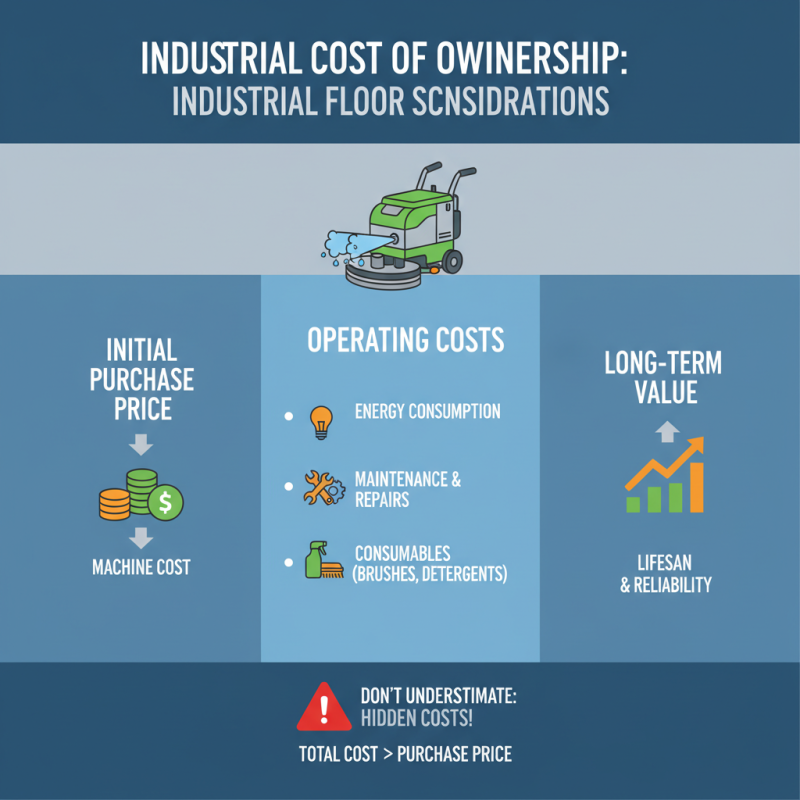

When considering the purchase of industrial floor scrubbers, budget is a critical aspect that can significantly influence your decision. Understanding the total cost of ownership beyond just the initial purchase price is essential. This includes factors such as maintenance costs, energy consumption, and the frequency of repairs over time. Many purchasers underestimate the long-term financial commitments associated with budget considerations, which can lead to unexpected expenditures down the line.

Additionally, it's important to evaluate the specific features that will provide the best value for your investment. Look for scrubbers that offer versatile capabilities or advanced technology that can enhance efficiency, even if they come at a higher upfront cost. Features like automation and improved cleaning paths may provide savings through reduced labor hours. Consider also the availability of warranties or service agreements, as these can mitigate long-term costs and offer peace of mind. Balancing these factors will allow you to make a well-informed decision that fits your operational needs while staying within budget constraints.

Maintaining your industrial floor scrubber is crucial for ensuring its longevity and optimal performance. Regularly inspecting and cleaning the machine after each use helps prevent the accumulation of dirt and grime that can impede functionality. It is essential to check the brushes and pads for wear and replace them as needed. Keeping the recovery tank clean is also important, as residual water and debris can lead to unpleasant odors and potential bacteria growth.

Another key aspect of maintenance is routine servicing. Scheduling professional maintenance checks can help identify issues before they escalate, ensuring that components like the motor and batteries are in good condition. Additionally, always store the scrubber in a dry, clean environment to protect it from moisture and dust accumulation. By following these maintenance tips, you can significantly extend the life of your floor scrubber while maintaining a high standard of cleanliness in your industrial space.